Cube Testing

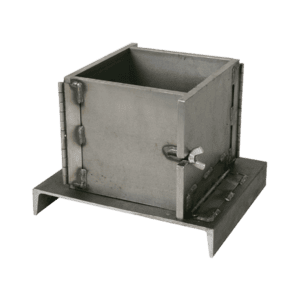

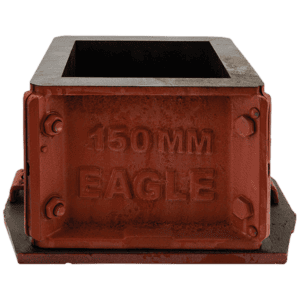

Concrete cube tests are performed to determine the compressive strength and other overall characteristics of concrete. In this destructive testing method, concrete cubes are crushed in a compression testing machine. The cubes used in this test have a dimension of 150 x 150 x 150 mm provided the largest aggregate does not exceed 20 mm. The testing requirement varies depending on whether it is being used in general construction or in commercial and industrial structures, and also varies based on the standards from specific geographical areas.

In the process, the cubes are usually cured and tested at 7 and 28 days, although depending on the specific project, curing and testing may also need to be done at 3, 5, 7 or 14 more days. The results are critical in the decision-making process that accompanies the engineering and construction of a new concrete project.

The concrete is first poured into a mold with the dimensions mentioned above and is then tempered to remove any gaps or voids. Then the specimens are removed from the molds and inserted into cooling baths until they have been sufficiently cured as spelled out in the project specifications.

Showing all 3 results