Description

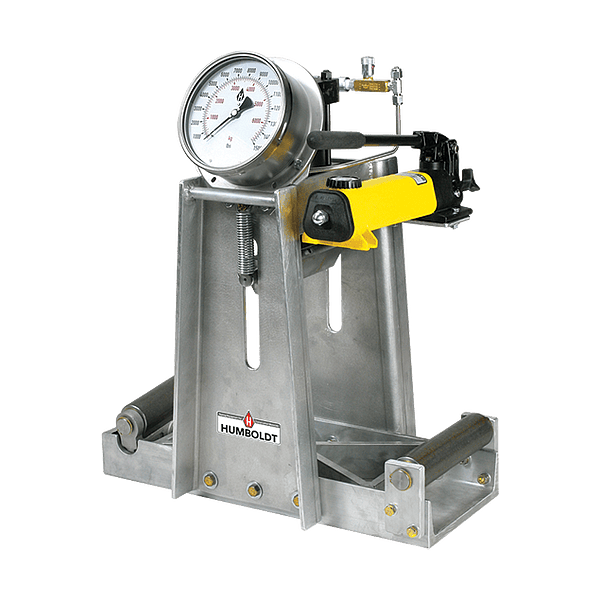

M&L Testing Equipment‘s Portable, Concrete Beam Testers are a great quality control tool for contractors, DOTs and consultants for quickly and accurately determining flexural strengths of concrete using 6″ x 6″ cross-section test beams.

These Beam Breakers are hydraulically driven units using the center-point loading method and provide continuous readings to the beam breaking point while retaining the maximum reading for accuracy and to eliminate lost data. The gauge also resets to zero for testing multiple beams. These beam breakers are constructed of lightweight aluminum, making them extremely portable for use at even the most remote of jobsites. Self-contained, portable concrete beam tester, which accurately and easily determines flexural strengths of 6″ x 6″ test beams of 16″ and 18″ lengths.

While not in full compliance with ASTM C293 since they use a hand pump, these beam testers can be used as an accurate quality control tool to determine whether curing concrete has met a specified flexural strength. In this type of application, a known flexural strength value is determined and is used as a go/no-go test parameter. Numerous government agencies including Illinois DOT have found its results acceptable for their purposes.

These beam testers provide dual registration of modulus at rupture between 15,000 lbf. and 0–6,800 kgf. The unit is calibrated by measuring the load applied on a calibrated load cell. The factory calibration is supplied at gauge readings of 10% FS, FS and 3 readings in between. Three load cell readings are averaged at each point to establish the correction for each point.

The H-3030A is a single-point tester for 16″ beams

The H-3032A is a single-point tester for 18″ beams

The H-3033A is a third-point tester for 18″ beams