Description

Supports the following standards: ASTM C666, AASHTO T161, PROCEDURE A

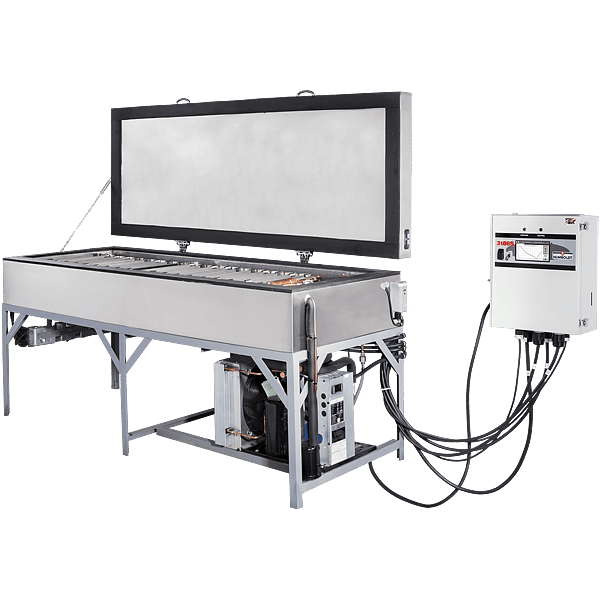

M&L Testing Equipment’s Elite Series, Freeze-Thaw Cabinet is used to measure the resistance of concrete to deterioration caused by repeated cycles of freezing and thawing. The HC-3186S.4F Freeze-Thaw is designed to test up to eighteen 3″ x 4″ x 16″ (76 x 102 x 406cm) concrete specimens simultaneously, with one being a control.

Key features of the Freeze-Thaw include:

- Fully automatic operation frees operator to perform other lab duties.

- Allows users to establish field control using correlations between concrete strength and durability

- Permits the evaluation of variables in concrete properties and conditioning.

- Useful in the evaluation of the durability of aggregates, as well as the properties of admixtures.

M&L Testing Equipment’s touch-screen controller provides you with full, graphical monitoring of all testing functions in a stand-alone application. Now you can have full, finger-tip control and monitoring of all testing functions with M&L Testing Equipment’s touch-screen controller, found on our Freeze-Thaw Cabinet. The seven-inch, waterproof screen provides at-a-glance monitoring of testing functions, in a real-time graphical display, without the use of a computer.

Now, in a stand-alone application, you will be able to run tests and display results while viewing tabulation, basic x-y graphs and temperature readings in real-time during the test, using user-defined, basic data acquisition. Test data is stored in the device and can be downloaded to a USB drive via the machine’s USB port.

The HC-3186S.4F Freeze-Thaw provides the following capabilities:

- User-created test control is possible, for changing freeze time, minimum temperature, maximum temperature and the number of cycles desired.

- Real-time, on-screen control and monitoring with graphing, allowing different data views to be chosen.

- Test data can be reviewed after a test is completed, which includes tabulation and graph views.

- Touch-screen interface for easy navigation.

- Complete report generation from with the M&L Testing Equipment NEXT software. Test data can also be exported to computers via a network or thumb drive.

- Remote control and monitoring via network and internet.

It is possible to have up to eight freeze-thaw cycles within a 24-hour period, however, the exact number of cycles is dependent upon the time required for the temperature at the center of the control prism to fall from 40 to 0°F (4.4 to -17.8°C) and then back to 40°F (4.4°C). The temperature at the center of the control specimen is controlled with the use of a 0.75HP (0.6KW) refrigeration unit and electric resistance heaters with fully automatic controls.

Current temperature of the control specimen can be checked by a glance at the large, 7″ color display on the controller. It is also possible to track the temperatures of freeze-thaw cycles in real-time with a glance at the display. These graphs and tabular data can be used to produce reports of tests within the M&L Testing Equipment NEXT software or downloaded to other computers or software for reports.

For corrosion resistance and long service life, the HC-3186S Freeze-Thaw features a stainless steel, 84″L x 32″W x 35.75″H (213 x 81 x 91cm) cabinet construction with 3″ (76mm) insulation on all sides. The internal test compartment measures 74″ x 26″ x 6″ (188 x 66 x 15cm). A 30-amp circuit is required for operation.

Freeze-Thaw Cabinet includes:

- (17) H-3185TA Stainless Steel Sample Tray, 3″ x 4″ x 16.375″ (76 x 102 x 406mm)

- (1) H-3185TSA Stainless Steel Sample Tray with spout, 3″ x 4″ x 16.375″ (76 x 102 x 406mm)

Order H-3195 freeze-thaw molds separately.