Description

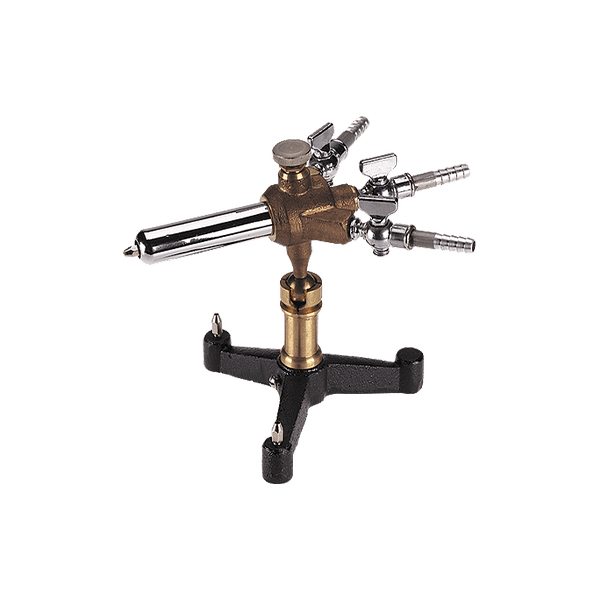

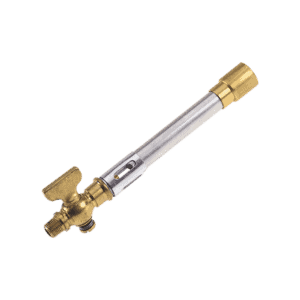

This bleeder valve unit provides small needle-sized to large brush flame patterns for fusing ore, working Pyrex and soft glasses, and performing other high-temperature melting applications. Extremely accurate flame direction, from three interchangeable burner tips, a telescoping mixing tube sleeve, a universal ball joint that directs the burner head to any angle, and a bleeder valve that controls the injection of air into the gas stream. Stopcock valves control the flow of gas, oxygen, and air. Brass construction.

Specifications:

• Gas type: Artificial, Natural and LP

• Inlet OD: 3/8″ (10mm)

• CFH*: 40 (60 with LP)

• BTU Output*: 41,000 (81,400 with LP)

• Overall Height: 8″ (203mm)

*Note: CFHs and BTU Outputs are figured on:

5 inch Water Column Pressures for Artificial and Natural Burners. 11 inch Water Column Pressures for LP Burners.